The very first French electric car battery factory is about to open its doors on Tuesday near Lens, a major industrial event for France, which wishes to guarantee its independence from the Chinese giant and even become an exporter by the end of the decade. This is one of Emmanuel Macron's hobbyhorses: reindustrialization will go through the production of batteries on French and European territory, while China has taken a considerable lead in this area.

ACC (Automotive Cell Company), an equal joint venture between TotalEnergies, Stellantis (born from the merger of PSA and Fiat-Chrysler) and Mercedes-Benz, is therefore the first to open its "gigafactory" in France. At present, only a handful are in operation in Europe, but investments are multiplying on the Old Continent, where around fifty projects have been announced in recent years. In the north of France, an emblematic territory of the deindustrialization of the country, four factories must emerge from the ground before the end of the decade.

The first, ACC in Billy-Berclau, which adjoins the historic PSA site in Douvrin, should be followed by the project of the Sino-Japanese group AESC-Envision in Douai (North), whose production will be intended for Renault from the start. 2025. The Grenoble start-up Verkor – supported by Renault, Schneider Electric and Arkema – plans to launch production at its Dunkirk plant from mid-2025, again for the Renault group. Finally, ProLogium, a Taiwanese group specializing in so-called "solid" batteries, announced in mid-May that it would also be setting up in Dunkirk, with production scheduled to start at the end of 2026.

At Billy-Berclau, production is scheduled to start this summer, and ACC is targeting 13 GWh of annual capacity by the end of 2024 with 600 jobs. From 2030, the objective is to employ 2,000 employees to produce 40 GWh, or the equivalent of 800,000 batteries per year, 500,000 according to Bercy. In the "Battery Valley", as politicians and industrialists have dubbed this territory stretching from Dunkirk to the former mining basin, this new industrial sector should lead to the creation of more than 20,000 jobs.

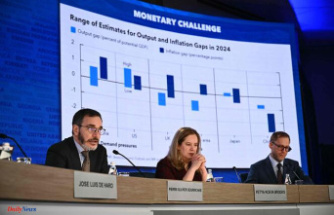

The stated ambition is great, but the accompanying challenges are just as great. France aims to be self-sufficient in battery production by 2027 to supply its automotive industry. As in other countries of the European Union, the sale of new thermal vehicles will be prohibited from 2035. The goal is even to manage to export, according to the Elysée. But France, even if it is better off than some of its European partners, remains handicapped by the price of its energy, compared to China or the United States, which massively subsidize this industry thanks to the Inflation Reduction Act (IRA ).

Another major challenge is the supply of critical metals. Lithium-ion batteries are very greedy in nickel, cobalt or manganese, whose production chain, from extraction to refining, is now largely controlled by China. There are ways to design batteries without using these materials – solid-state batteries, lithium-sulfur batteries – but these technologies are still only experimental. In Billy-Berclau, ACC should evolve its technology from lithium-ion batteries to new generation, solid batteries. The company, which has invested 7 billion euros and plans a factory in Germany and another site in Italy, has received 1.3 billion in French and German public aid.

The four French "gigafactories" (very large factories) should pave the way for an ecosystem attracting suppliers of battery materials and components, as well as recycling sites. On May 12, Mr. Macron thus announced the establishment in Dunkirk of a cathode production site – one of the two electrodes making up a battery – financed by the Chinese XTC and the French Orano.