Vehicle parts made of light materials are twice as sustainable: Smaller and less heavy batteries can be installed with the same range, so that charging times are reduced, less installation space is required and costs are saved.

Electric cars are currently the first choice when it comes to reducing CO2 emissions in private transport. And indeed, e-cars are not only interesting for reasons of climate protection, but also in terms of consumption costs. While a gasoline engine is currently around 16 euros/100 km (consumption 8 l/100 km) in terms of pure fuel, the electric car only costs around 8 euros/100 km (consumption 20 kwh/100 km).

But the Stromer have a problem - their ecological balance leaves something to be desired and they are relatively heavy. In order to get this problem under control, the German Aerospace Center (DLR) has launched the CosiMo (Composites for Substainable Mobility) project, which is researching how e-cars can be made lighter and more sustainable at the same time.

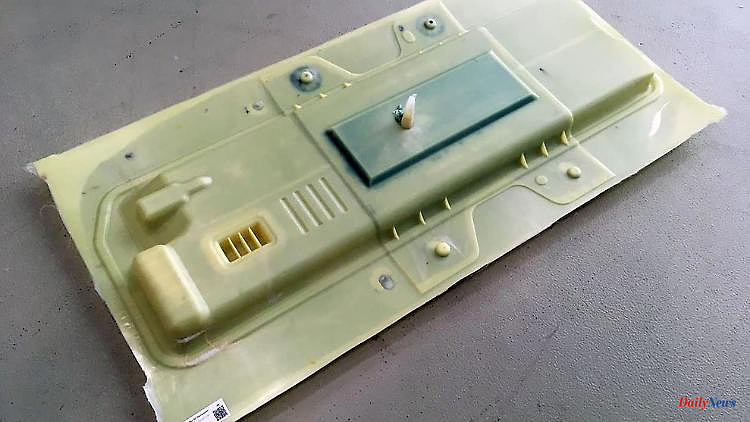

The magic word is lightweight construction. In a first step, the researchers at DLR took on the batteries. A conventional battery housing currently weighs around 300 kg. The use of fiber-reinforced plastics has made it possible to reduce the weight by up to 40 percent.

On the one hand, this saves aluminum and steel, and on the other hand, the plastics used are recyclable and therefore sustainable. Another point is the lower overall weight of the vehicle. The lightweight construction enables the installation of smaller and therefore lighter batteries with the same range. This leads to cost savings and reduces the charging times of the Stromer.

CosiMo is a joint project to research new materials and manufacturing processes for sustainable mobility, in which a total of 14 partners from research and industry are involved. The project, which started in 2018, ran until the end of 2021 and was funded by the Bavarian State Ministry for Economic Affairs, Regional Development and Energy.

6